18

2022

-

07

Market Size Analysis and Investment Direction Research of China's Servo Motor Industry

From a global demand perspective, with the advancement of servo system technology and the penetration of downstream application markets, the global demand for servo motors has been increasing year by year.

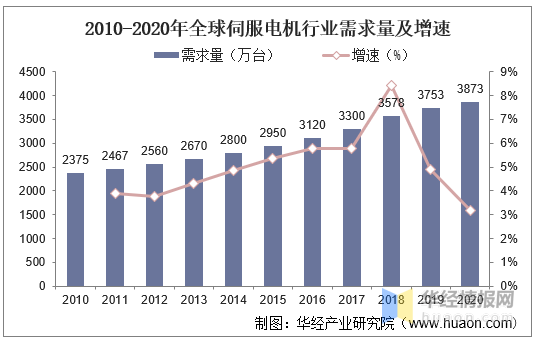

From a global demand perspective, with the advancement of servo system technology and the penetration of downstream application markets, the global demand for servo motors has been increasing year by year. According to statistics, since 2015, due to the rise of industrial robots in downstream industries, it has become a new driving force for the growth of global servo motor demand. In 2020, the annual global demand for servo motors was approximately 38.73 million units, a year-on-year increase of 3.20%, and the average annual compound growth rate was 5.01%, maintaining a steady growth trend.

Global Servo Motor Industry Demand and Growth Rate (2010-2020)

Data Source: Compiled from Publicly Available Information

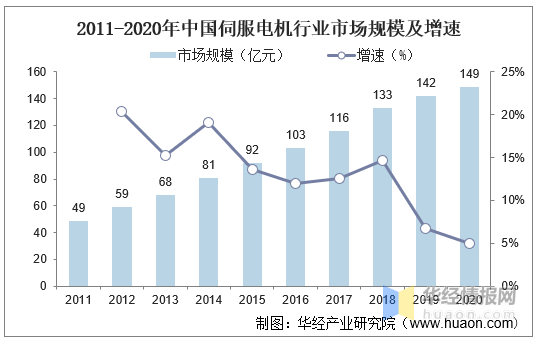

The truly widespread application of servo products in China has only been for over a decade, and it is still in the growth stage. Due to the advantages of servo motor systems in terms of precision, torque frequency, and overload capacity, they have a wider range of applications than stepper motor systems. They have been widely used in machine tools, textile machinery, printing machinery, and packaging machinery. Simultaneously, with the rapid expansion of industries such as industrial robots and electronic manufacturing equipment in recent years, the application scale of servo motors in emerging industries has grown rapidly, and the overall market size has considerable growth potential. According to statistics, in 2020, the market size of servo motors in China was 14.9 billion yuan, an increase of 4.93% year-on-year, and the average annual compound growth rate was 13.15%, indicating a period of rapid growth.

Market Size and Growth Rate of China's Servo Motor Industry (2011-2020)

Data Source: Compiled from Publicly Available Information

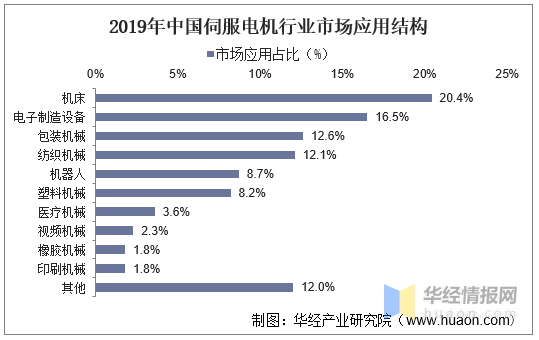

The downstream Applications of servo drive systems are extensive. Machine tools, 3C electronic equipment manufacturing, packaging machinery, textile machinery, plastic machinery, medical equipment, food machinery, rubber machinery, and printing machinery account for a large proportion of the applications. According to statistics, in 2019, the largest application area for servo motors in China was machine tools (especially CNC machine tools), accounting for 20.4%. This was followed by electronic manufacturing equipment, packaging machinery, textile machinery, plastic machinery, and industrial robots, with proportions of 16.5%, 12.6%, 12.1%, 9.6%, and 6.20%, respectively. The following section will focus on analyzing the demand for servo motors in the machine tool industry, electronic specialized equipment industry, textile machinery, and industrial robots industries.

Application Structure of China's Servo Motor Industry Market in 2019

Data Source: Compiled from Publicly Available Information

Huajing Industry Research Institute has conducted an in-depth analysis of the current situation, industry upstream and downstream industry chain, competitive landscape, and key enterprises in China's servo motor industry. This aims to minimize the investment risks and operating costs of enterprises and improve their competitiveness. Using a variety of data analysis techniques, the Institute predicts industry development trends, enabling enterprises to seize market opportunities in a timely manner. For more detailed information, please refer to the "2022-2027 China Servo Motor Industry Market Overview and Investment Direction Research Report" published by Huajing Industry Research Institute.

(Declaration: This content is transferred from the Internet. Please contact us for deletion if there is any infringement.)

Servo,Motor

Previous article

Previous article

Latest developments

2025-03-28

The Use and Maintenance of Cylinder Liner Bearing Boring Machines

Cylinder block bearing boring machines are used for automobile engine repair, mainly for boring the main bearing and camshaft bearings of engine cylinder blocks.

2025-03-28

Inspection and repair methods for the planarity of the cylinder head working surface

The inspection and repair methods for the flatness of the cylinder head working surface are basically the same as those for the flatness of the cylinder block, except for different repair specifications.

2025-03-28

Repair of the cylinder body main bearing bore

Common failure modes can be roughly divided into four categories: wear, deformation, corrosion, and hole cracking. Methods for repairing the size of the main bearing bore include traditional methods and two new processes: zinc-aluminum alloy electroplating and nickel wire gas tungsten arc welding. Key points to note during the repair process.

2025-03-28

Basic Overview and Classification of Boring Machines

Boring Machine Overview: A machine tool that primarily uses a boring bar to bore pre-machined holes in a workpiece. Typically, the boring bar rotates as the main motion, and the boring bar or workpiece moves as the feed motion.

2025-03-28

Introduction to Milling Machine and Grinding Machine Fundamentals

In a machining center, the process of machining using a milling machine and a grinding machine is called milling and grinding.